- Plastic Piping Systems & Automatic Valves

Industrial Piping Systems

-

SEKISUI

SEKISUI- Catalogue DOWNLOAD

- SCH80 Pipe & Fittings ESLON VALVES Mefco

ESLON SCH80 PVC & CPVC Piping Systems

ESLON SCH80 Piping Systems are produced in accordance with ASTM Standards.

Type Material

(Cell Classification No.)Dimensions Commercial Classification PVC Sch80 ASTM D-1784

(12454)ASTM D-1785 Type I, Grade 1, PVC 1120 CPVC Sch80 ASTM D-1784

(23447)ASTM F-441 Type IV, Grade 1, CPVC 4120 - Advantages of SCH80 PVC & CPVC

-

1.Excellent corrosion resistance and chemical resistance

2.Excellent impact resistance and pressure resistance

3.Smooth internal surface; less friction-caused loss and fast flow speed

4.Easy piping work and construction cost saving

5.NSF approved pipe with excellent sensitivity for portable water

6.All SEKISUI products have NSFPW mark displayed on their surface.

Features of ESLON SCH80

ESLON SCH80 Pipe and Fitting have NSF 14 and NSF 61 approvals.

NSF 14

Requirements of Plastic Piping System Components and Related MaterialsNSF 61

Requirements of Drinking Water System Components - Health EffectsAll products manufactured in conformance to NSF 14 and NSF 61 have NSFPW mark on its surface.

Pipe & Fitting Size : 1/2” – 24”

SCH80 PVC Max Temp. : 60℃

SCH80 CPVC Max Temp. : 93℃

ESLON PVC PIPE • FITTINGS UV STRONG

Weather-proof resin that is resistant to ultraviolet (UV) rays has achieved excellent anti-UV performance.

-

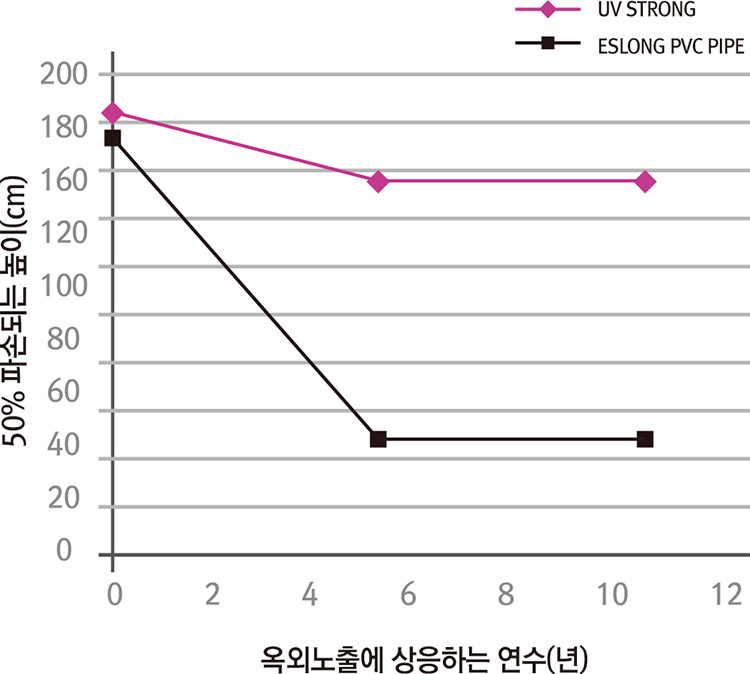

- Weather-resistance promotion evaluation (impact resistance)

-

•According to promotion test for outdoor exposure, decrease in impact performance was approx. 10% in 10 years.

-

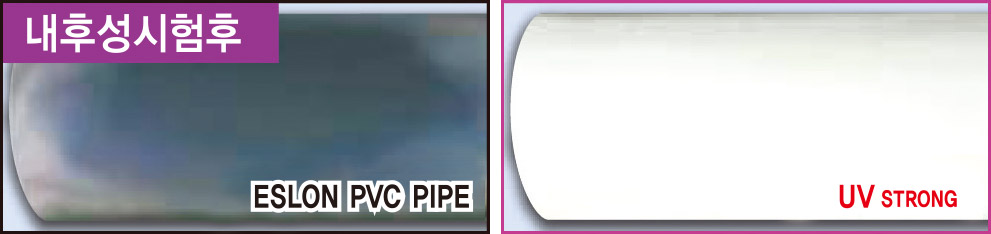

- Weather-resistance promotion evaluation (exterior design)

-

•It controls discoloration for exterior design and decrease in physical properties.

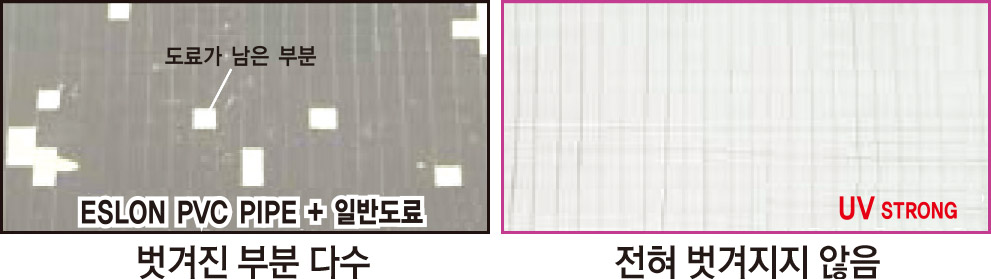

- Delamination Test

-

•It has been proven that dissecting is very difficult due to high weather-resistance. (Carried out peeling / attaching tape on the sample 5 times)

※ Note: JIS K 5600-5-6 cross cut method evaluation

-

SPEARS

SPEARS- Catalogue DOWNLOAD

- PVC SCH80 Pipe & Fittings CPVC SCH80 Pipe & Fittings Valves

Schedule 80 PVC, CPVC Fittings, Valves.

SPEARS SCHEDULE (Schedule, SCH) Series PVC and CPVC piping systems are approved by NSF (National Sanitation Foundation) in terms of materials, specification and test defined by ASTM. Compared to general metal piping systems, SPEARS SCHEDULE Piping Systems have excellent corrosion resistance and chemical resistance. Therefore, they are very suitable for not only hygienic pipes for drinking water and food, but various industrial pipes for semiconductor, ultra pure water, chemical, water and sewage, and waste water.

In particular, all NSF approved products have NSF mark displayed on their surface. Non-NSF-approved SCH 80 PVC and CPVC products (in other words, products without NSF mark) produced in other regions than the US and Canada simply comply with ANSI standards.

- Features and Advantages of SCH 80 PVC & CPVC Products

-

•Excellent impact resistance, pressure resistance, and heat resistance

•Maximum use temp.: CPVC SCH80 piping system: 95°C

•PVC SCH80 piping system : 60°C

•Excellent chemical resistance and corrosion resistance

•non availability for Solvent chemical products; See technical materials before use

•Because of excellent abrasion resistance, it is suitable to pipes for waste water and slurry.

•Because of low thermal conductivity, it has excellent warming and cold reserving effects; and no dew condensation occurs.

•Because of smooth internal surface, it features less friction-caused loss, fast flow speed, and no scale.

•It's burning-resistance material has the capability of fire-extinguishing at fire

•It's excellent electrical insulation feature prevents leakage or electricity-induced corrosion.

•Because of easy piping work, it features excellent workability, construction cost saving, and economic maintenance.

•It is the most hygienic piping system with NSF approval.

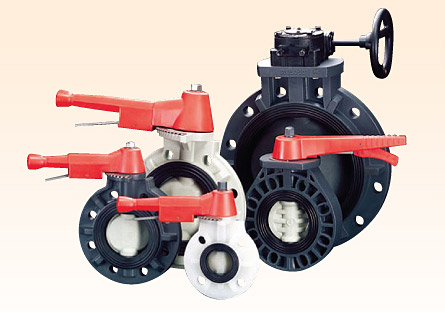

- Ball Valve

- Butterfly Valve

- Diaphragm Valve

- Check Valve

- Strainers

- Labwaste

- SCH80 PVC

- SCH80 CPVC

ASTM STANDARD SPECIFICATIONS FOR SCHEDULE PIPING SYSTEMS DESCRIPTIONS MATERIAL SCOPE PVC CPVC PVC CPVC SCH 40, 80, 120 PIPE D-1784 D-1784 D-1785 F-441 SCH 40, 80, FITTING(SOCKET) D-1784 D-1784 D-2467 F-439 SCH 40, 80, FITTING(THREAD) D-1784 D-1784 D-2464 F-437 IPS WELD-ON SOLVENTS D-1784 D-1784 D-2564 F-493 -

G.F HARVEL

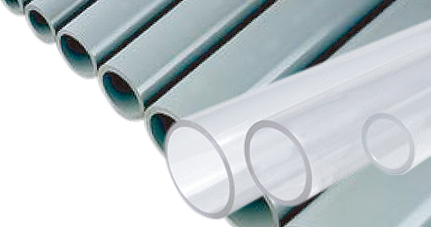

G.F HARVEL- Catalogue DOWNLOAD

- SCH80 PVC & CPVC Pipe

Schedule 80 PVC, CPVC Pipe

Schedule 80 PVC, CPVC Pipe// Founded in 1966 in Easton, Pennsylvania of the US, HARVEL specializing in making schedule series (SCH 40, SCH 80, SCH 120) PVC & CPVC pipes and diverse shapes (rods and bars). With its best facilities recognized by other manufacturers in the field, the company produces high-quality PVC, CPVC SHC 80 pipes up to 24"(600mm).

- SCH80 PVC

- SCH80 CPVC

- Transparent piping

- CPVC ROD

- Flattening Resistance

Test Scene

PVC SCHEDULE PIPE SPECIFICATIONS Nominal PIPE SIZE(in) PVC SCHEDULE PIPE External Diameter

(O.D mm)Mean Internal Diamete

(I.D mm)Minimum Thickness

(mm)Sandard Weight

(Ib/ft)Maximum Use Pressure

(@23℃),(kg/㎠)40 80 120 40 80 120 40 80 120 40 80 120 40 80 120 1/8

1/4

3/8

1/2

3/4

1

1.1/4

1.1/2

2

2.1/2

3

3.1/2

4

5

6

8

10

12

14

16

18

20

2410.29

13.72

17.15

21.34

26.67

33.40

42.16

48.26

60.33

73.03

88.90

101.60

114.30

141.30

168.28

219.08

273.05

323.85

355.60

406.40

457.20

508.00

609.606.32

8.74

12.01

15.29

20.42

26.14

34.54

40.39

51.99

62.10

77.27

89.43

101.55

127.41

153.19

201.73

253.39

301.98

332.05

379.48

426.95

476.07

572.624.95

7.16

10.24

13.36

18.34

23.77

31.88

37.49

48.59

58.17

72.75

84.48

96.16

121.11

145.01

192.15

241.12

286.87

315.21

361.01

406.76

452.48

544.02

12.19

17.53

22.63

30.58

36.14

46.86

56.87

70.05

90.78

138.02

182.601.73

2.24

2.31

2.77

2.87

3.38

3.56

3.68

3.91

5.16

5.49

5.74

6.02

6.55

7.11

8.18

9.27

10.31

11.10

12.70

14.27

15.06

17.452.41

3.02

3.20

3.73

3.91

4.55

4.85

5.08

5.54

7.01

7.62

8.08

8.56

9.53

10.97

12.70

15.06

17.45

19.05

21.41

23.80

26.19

30.94

4.32

4.32

5.08

5.46

5.72

6.35

7.62

8.89

11.10

14.27

18.240.051

0.086

0.115

0.170

0.226

0.333

0.450

0.537

0.720

1.136

1.488

1.789

2.118

2.874

3.733

5.619

7.966

10.534

12.462

16.286

20.587

24.183

33.6520.063

0.105

0.146

0.213

0.289

0.424

0.586

0.711

0.984

1.500

2.010

2.452

2.938

4.078

5.610

8.522

12.635

17.384

20.852

26.810

33.544

41.047

58.233

0.236

0.311

0.464

0.649

0.787

1.111

1.615

2.306

3.713

7.132

11.27756.95

54.84

43.59

42.19

33.75

31.64

26.01

23.20

19.69

21.09

18.28

16.87

15.47

13.36

12.66

11.25

9.84

9.14

9.14

9.14

9.14

8.44

8.4486.48

79.45

64.68

59.76

48.51

44.29

36.56

33.05

28.12

29.53

26.01

24.61

22.50

20.39

19.69

17.58

16.17

16.17

15.47

15.47

15.47

15.47

14.76

71.01

54.14

50.62

42.19

37.97

33.05

33.05

30.94

30.23

26.01

26.72CPVC SCHEDULE PIPE SPECIFICATIONS Nominal PIPE SIZE(in) CPVC SCHEDULE PIPE External Diameter

(O.D mm)Mean Internal Diamete

(I.D mm)Minimum Thickness

(mm)Sandard Weight

(Ib/ft)Maximum Use Pressure

(@23℃),(kg/㎠)40 80 40 80 40 80 40 80 40 80 1/4

3/8

1/2

3/4

1

1.1/4

1.1/2

2

2.1/2

3

3.1/2

4

5

6

8

10

12

14

16

18

20

2413.72

17.15

21.34

26.67

33.40

42.16

48.26

60.33

73.03

88.90

101.60

114.30

141.30

168.28

219.08

273.05

323.85

355.60

406.40

457.20

508.00

609.608.74

12.01

15.29

20.42

26.14

34.54

40.39

51.99

62.10

77.27

89.43

101.55

127.41

153.19

201.73

253.39

301.98

332.05

379.48

426.95

476.07

572.627.16

10.24

13.36

18.34

23.77

31.88

37.49

48.59

58.17

72.75

84.48

96.16

121.11

145.01

192.15

241.12

286.87

315.21

361.01

406.76

452.48

544.022.24

2.31

2.77

2.87

3.38

3.56

3.68

3.91

5.16

5.49

5.74

6.02

6.55

7.11

8.18

9.27

10.31

11.10

12.70

14.27

15.06

17.453.02

3.20

3.73

3.91

4.55

4.85

5.08

5.54

7.01

7.62

8.08

8.56

9.53

10.97

12.70

15.06

17.45

19.05

21.41

23.80

26.19

30.940.096

0.128

0.190

0.253

0.371

0.502

0.599

0.803

1.267

1.660

1.996

2.363

2.874

4.164

6.268

8.886

11.751

13.916

18.167

22.965

29.976

37.5390.117

0.162

0.238

0.322

0.473

0.654

0.793

1.097

1.674

2.242

2.735

3.277

4.078

6.258

9.506

14.095

19.392

23.261

29.891

37.419

45.879

64.95954.84

43.59

42.19

33.75

31.64

26.01

23.20

19.69

21.09

18.28

16.87

15.47

13.36

12.66

11.25

9.84

9.14

9.14

9.14

9.14

8.44

8.4479.45

64.68

59.76

48.51

44.29

36.56

33.05

28.12

29.53

26.01

24.61

22.50

20.39

19.69

17.58

16.17

16.17

15.47

15.47

15.47

15.47

14.76Pressure correction factor for using SCH80 PVC & CPVC piping systems according to Temp. Temp.(℃) SCH80 PVC SCH80 CPVC 23 1.00 1.00 27 0.88 0.93 32 0.75 0.86 38 0.62 0.77 43 0.51 0.72 49 0.40 0.65 55 0.31 0.57 60 0.22 0.50 66 Disabled 042 71 0.40 77 0.29 82 0.25 94 0.20

-

SHIE-YU

SHIE-YU- Catalogue DOWNLOAD

- SCH80 PVC, CPVC Pipe

-

SCH80 PVC, CPVC Pipe & Clear PVC Pipe, Double Containment Piping Systems

IPEX Management Inc., which was established in 1951, is providing different kinds of high-quality thermoplastic pipe materials such as schedule series (SCH40, SCH80) PVC, CPVC pipe, transparent pipe, and double containment piping. Especially, it manufactures PVC and CPVC SCH80 pipe to a maximum length of 24” (600 mm).

SCHEDULE 40 PVC/CPVC PIPE PVC/CPVC SCHEDULE 40 PVC SCH40 PVC SCH40 CPVC SCH40 CPVC SCH40 Maximum Use Pressure

(at 23℃) (kg/cm²)Diameter(in.) External Diameter(O.D/mm) Minimum Thickness(mm) Mean Internal Diamete(mm) Sandard Weight(lb/ft) Sandard Weight(kg/m) Sandard Weight(lb/ft) Sandard Weight(kg/m) 1/2 21.3 2.76 15.26 0.17 0.253 0.18 0.269 42.18 3/4 26.70 2.86 20.46 0.22 0.327 0.24 0.354 33.75 1 33.40 3.38 26.14 0.33 0.491 0.35 0.522 31.64 1-1/4 42.15 3.56 34.53 0.44 0.655 0.47 0.705 26.02 1-1/2 48.25 3.68 40.37 0.52 0.774 0.57 0.843 23.20 2 60.35 3.90 52.03 0.70 1.042 0.76 1.129 19.69 2-1/2 73.00 5.16 62.08 1.11 1.652 1.20 1.781 21.09 3 88.90 5.48 77.28 1.45 2.158 1.57 2.336 18.28 4 114.30 6.02 101.58 2.07 3.081 2.23 3.323 15.47 5 141.30 6.54 127.42 2.81 4.182 13.36 6 168.30 7.10 153.22 3.65 5.432 3.93 5.853 12.66 8 219.05 8.18 201.71 5.50 8.185 5.92 8.812 11.25 10 273.05 9.26 253.41 7.78 11.578 8.40 12.497 9.85 12 323.90 10.30 302.04 10.30 15.328 11.13 16.565 9.14 14 355.60 11.13 332.03 12.18 18.130 13.16 19.590 9.14 16 406.40 12.70 379.38 15.96 23.75 17.21 25.617 9.14 18 457.20 14.27 429.46 20.11 29.93 9.14 20 508.00 15.06 476.07 23.62 35.15 8.44 24 609.60 17.45 572.62 32.87 48.92 8.44 SCHEDULE 80 PVC/CPVC PIPE PVC/CPVC SCH80 PVC SCH80 PVC SCH80 CPVC SCH80 CPVC SCH80 Maximum Use Pressure

(at 23℃) (kg/cm²)Diameter(in.) External Diameter(O.D/mm) Minimum Thickness(mm) Mean Internal Diamete(mm) Sandard Weight(lb/ft) Sandard Weight(kg/m) Sandard Weight(lb/ft) Sandard Weight(kg/m) 1/4 13.7 3.02 7.67 0.10 0.150 79.44 3/8 17.1 3.20 10.74 0.14 0.210 64.68 1/2 21.3 3.72 15.26 0.21 0.313 0.22 0.335 59.76 3/4 26.70 3.90 18.38 0.28 0.417 0.31 0.456 48.51 1 33.40 4.54 23.78 0.41 0.610 0.45 0.663 44.29 1-1/4 42.15 4.84 31.87 0.57 0.848 0.62 0.919 36.56 1-1/2 48.25 5.08 37.49 0.69 1.026 0.75 1.115 33.05 2 60.35 5.54 48.61 0.96 1.429 1.04 1.545 28.12 2-1/2 73.00 7.00 58.16 1.46 2.173 1.58 2.356 29.53 3 88.90 7.62 72.74 1.96 2.917 2.12 3.153 26.02 4 114.30 8.56 96.16 2.87 4.271 3.10 4.610 22.50 5 141.30 9.52 121.12 2.81 4.182 20.39 6 168.30 10.96 145.04 5.48 8.155 5.91 8.793 19.69 8 219.05 12.70 192.13 8.32 12.382 8.98 13.366 17.58 10 273.05 15.06 241.13 11.81 17.576 13.32 19.816 16.17 12 323.90 17.44 286.92 16.98 25.269 18.35 27.310 16.17 14 355.60 19.05 315.22 20.34 30.270 21.96 32.680 15.47 16 406.40 21.41 361.29 26.03 38.74 28.09 41.801 15.47 18 457.20 23.80 406.76 32.76 48.75 15.47 20 508.00 26.19 452.48 40.09 59.66 15.47 24 609.60 30.94 544.02 56.88 84.65 14.77 Correction factor for pressure used in SCH80 PVC and CPVC pipe materials according to temperature change temperature(℃) 23 27 32 38 43 49 54 60 66 71 77 82 93 SCH80 PVC 1.00 0.88 0.75 0.62 0.50 0.40 0.30 0.22 Disabled SCH80 CPVC 1.00 0.96 0.91 0.82 0.74 0.65 0.58 0.50 0.45 0.40 0.33 0.25 0.20

-

FIP

FIP- Catalogue DOWNLOAD

- U-PVC, C-PVC, PP-H

High Technics & High Quality

U-PVC, C-PVC, PP-H, PVDF PIPING SYSTEMS

FIP, a company affiliated with Aliaxis Group S.A. (IPEX, Durapipe UK, Harrington USA Holdings) established in 1954, is manufacturing and supplying U-PVC, C-PVC, PP-H, PVDF piping and manual valves, automatic valves, and instrument products. It is providing excellent quality products, which have been recognized for their quality all over the world including in Europe, to different kinds of industrial fields such as water-processing, chemical equipment, steel manufacturing, and shipbuilding and is building a good reputation.

Especially, they are providing patented products, the manual ball valve with the Dual-Block-®system, the diaphragm valve with the Diallock-®system, and the butterfly valve equipped with a handle locking function.

- Materials

- •U-PVC, C-PVC, PP-H, PVDF

- SIZE

-

•Ball Valve 16A-100A (1/2"-4")

•Butterfly Valve 40A-400A (1.1/2"-16")

•Diaphragm Valve 16A-100A (1/2"-4")

•Check Valve 16A-300A (1/2"-12")

•Y-strainer 16A-100A (1/2"-4")

- Specifications

- ㆍJIS,ANSI,DIN SOCKET TYPE, JIS 10K, ANSI 150#, ISO DIN FLANGE TYPE

- FIP Manual Valve product characteristics

-

1.Union nuts locking system that has received patent rights for the VKD dual block ball valve model prevents leakage of chemical substances that occurs due to the loosening of union nuts and it reinforces valve stability.

2.The DK dial-lock diaphragm valve can apply locking on 300 positions and achieve large-scale flow rate based on new design.

3.Stroke limiter and travel stop can be attached on the DK manual diaphragm valve.

4.Locking for FK butterfly valves can be applied to 10 positions. U-PVC, C-PVC, PP-H, and PVDF materials can be used on the PP-GR valve body. Direct assembly can be carried out for Automatic Valves.

5.U-PVC, C-PVC, PP-H, and PVDF materials can be used for supply of different kinds of valves such as ball, diaphragm, butterfly, check, and strainer.

U-PVC, C-PVC, PP-H, PVDF Automatic Valves

- Pneumatic Ball Valve

(15-50A)

- Pneumatic Ball Valve

(65A-100A)

- Electric Ball Valve

- Pneumatic Three Way

Ball Valve

- Pneumatic Diaphragm Valve

- Pneumatic Butterfly Valve

- Automatic Valves

-

•Pneumatic, Electric ball valve

•Pneumatic, Electric butterfly valve

•Pneumatic diaphragm valve with accessories

- FIP Automatic Valve product characteristics

-

1.A PR-GR POWER QUICK Module applied with VKD pneumatic and electric ball valve. Direct assembly can be carried out without having to apply processing on VKD automatic valve assembly. Specifications such as ISO5211 F03, F04, and F05 are applied on actuator contact parts. Selection of POWER QUICK is available depending on actuator torque size.

2.U-PVC, C-PVC, PP, and PVDF disc materials are applied on FK pneumatic, electric butterfly valve PP-GR body and JIS, ANSI, DIN dimension can be applied.

3.DK, DKM, VM pneumatic diaphragm valve DK pneumatic diaphragm valve has achieved maximum performance and flow rate. Assembly of EPDM, FPM, PTFE diaphragm materials can be carried out on U-PVC, C-PVC, PP, PVDF body. Actuator body is applied with PP-GR material that is based on strong and compact piston actuator type and NC, NO, DA versions can be selected. Assembly of accessories such as solenoid valves, positioners, and limit switches is available.

-

SHIE-YU

SHIE-YUPlastic valves with excellent quality and diverse sizes

Since its foundation in 1973, SHIE YU, which is the first thermoplastic valve manufacturer in Taiwan, has been producing valves and pipes. Over the last 30 years, the company has taken the leadership in product quality thanks to its cutting-edge technology and process.

As a result, its products being exported to more than 40 countries are widely used and applied to piping systems. The company has good reputation as a reliable supplier.

Produceable material : UPVC, CPVC, PP, PVDF

- UNION BALL VALVE

- 15A(1/2")-100A(4")

- FLANGE

- 15A(1/2")-600A(24")

- UNION

- Union

- 15A(1/2")-600A(4")

- New Union

- 10A(3/8")-80A(3")

- CHECK VALVE

- Ball Check Valve

- 15A(1/2")-100A(4")

- Swing Check Valve

- 25A(1")-200A(8")

- Wafer Check Valve

- 40A(1-1/2")-600A(24")

- SEDIMENT STRAINERS

- Y Strainer

- 15A(1/2")-100A(4")

- T Strainer

- 15A(1")-200A(8")

- STRONG BALL VALVE

- 15A(1/2")-100A(4")

- DIAPHRAGM VALVE

- 15A(1/2")-250A(10")

- BUTTERFLY VALVE

- Lever Type

- 50A(2")-200A(8")

- Gear Type

- 50A(2")-1200A(48")

- Large Size Butterfly Valve

- 700A(28")-1200A(48")

Industrial PP and PVDF pipes,

SHIE YU, a manufacturer of industrial PP and PVDF pipes, fittings and valves, is equipped with various sizes of product lines and produces and supplies the best quality PP and PVDF piping systems with customized-quality resin.

- PVDF Pipe & Fittings

-

PVDF Butt Fusiond63-d630 ( PN10/SDR33 )

PVDF Butt Fusiond20-d315 ( PN16/SDR21 )

PVDF Socket Fusiond20-d110 ( PN20/SDR17 )

- PP-H Pipe & Fittings

-

PP-H Butt Fusiond20-d630 ( PN10/SDR11 )

PP-H Socket Fusiond20-d110 ( PN10/SDR11 )

Dimension Standard DIN 8077/8078

-

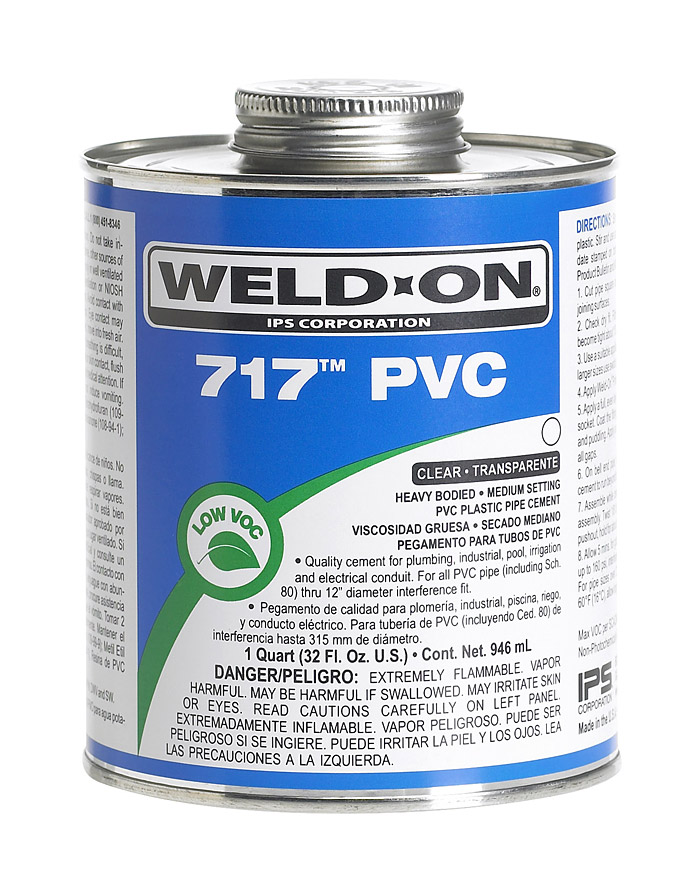

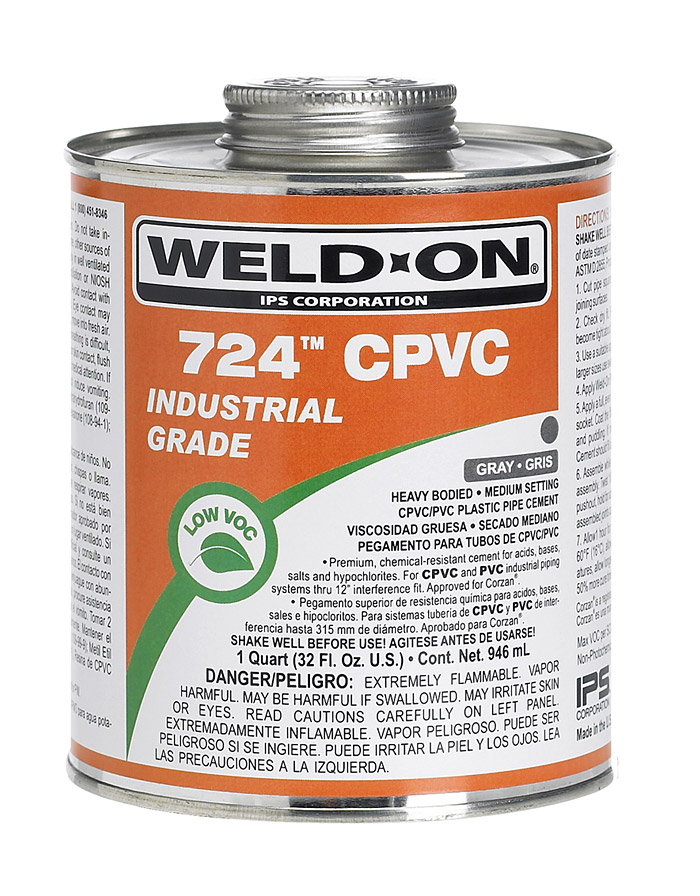

IPS WELD-ON

IPS WELD-ON- Catalogue DOWNLOAD

- IPS WELD-ON

PVC, CPVC, Solvent Cements for Firefighting

Founded in 1954, IPS takes the leadership in researching and developing plastic solvent cements last 50 years. In particular, the company became the first enterprise of producing reliable solvent cements used for connection of PVC, CPVC, and ABS piping systems.

To establish basic ASTM(American Society for Testing and Materials) standards about the products, the company had made a study closely with ASTM researchers. As a result, the current perfect ASTM standards were set out.

Today, IPS WELD-ON products are recognized well in the world in terms of quality, and have widely been used in as many as 100 countries.

- 717Adhesives for PVC

- 714Adhesives for CPVC

- 724Adhesives for CPVC

- P-70 PRIMER

-

PLASTICON

PLASTICON- Catalogue DOWNLOAD

- 제품명 확인 중

HAYWARD Maker was established in 1923 and has been manufacturing equipment in 6 areas such as Europe, Australia, Canada, the U.S., and China. It is providing special direct mounting ball valves, butterfly valves, wafer check valves, basket strainers, and bag filters to different kinds of areas such as water-processing, waste water processing, chemical processes, aquariums, farms, and swimming pools.

- UNION BALL VALVE (TBH)

- PVC, CPVC

- 1/4" - 2"

- BUTTERFLY VALVE (BYV)

- PVC, CPVC, GFPP

- 2" - 12"

- WAFER CHECK VALVE (WCV)

- PVC, CPVC

- 2" - 8"

- BASKET STRAINER (SB)

- PVC, CPVC, GFPP, EASTAR

- 1/2" - 4", 6" - 8" (PVC, CPVC)

- BAG FILTERS (FLV)

- PVC, CPVC, GFPP

- PRESSURE RELIEF VALVE (RPV)

BACK PRESSURE VALVE (PBV) - PVC, CPVC, PP, PVDF

- 1/2" - 2"

- PRESSURE RELIEF VALVE (RV)

- PVC, CPVC

- 1/2" - 2"

-

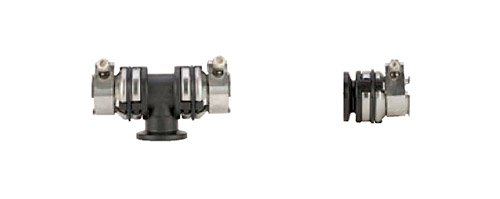

CLIC

CLIC- Catalogue DOWNLOAD

- CLIC

EFCO Fixing Technology Ltd was established in 1924 and is one of the leading retrofitting and renovations technology experts in Switzerland that is making innovative fixing devices.

It provides a wide-range of product along with systematic solutions and different kinds of application knowledge based on a mutual-supplementary multi-channel strategy.

CLIC (high-quality co-polymer material)

Can be installed at -10°C – 90°C

Suitable loading weight

Alternative for stainless objects

Zero-halogen that is approved from IEC 60754-2

Can be recycled

Has great UV resistance and general chemical resistance

International certification KIWA, UL

Widely-used and suitable for indoors

CLIC TOP (high-quality polyamide 12)

Can be applied at -40°C – 110°C

High loading weight

Alternative for V4A (stainless alloy)

Zero-halogen that is approved from IEC 60754-2

Can be recycled

UV resistance, weather resistance

Chemical resistance (alkaline & acid, exhaust fumes, fuels)

International certification KIWA, UL

Suitable for special climates or certain areas and industrial complexes Wide-range application

- Wide-range application

-

•Product type can be selected depending on environmental conditions and application field.

•CLIC : Solution that is approved for general use

•CLIC TOP : It can meet maximum requirements (non-flammability, shock resistance, chemical resistance) needed for indoor and outdoor use.

•Also, various colors can be used.

-

BANJO

BANJO- Catalogue DOWNLOAD

- BANJO

PP Plastic Valves, Cam Lever Couplings.

The US Banjo is a leading manufacturer of the products to transport agricultural and industrial chemicals. In particular, the company specializes in supplying PP products formed with tempered glass on the basis of its innovative design and technical engineering.

Banjo supplies the products to transport fluid, such as valves, electric auto valves, manifolds, and systems, in the world.

- VALVES

- DRY-DISCONNECTS

- PINCH VALVES

- IBC/TANK ACCESSORIES

- CHECK VALVES

- CAM LEVER COUPLINGS

- ELECTRIC VALVES

- GARDEN HOSE FITTINGS

- MANIFOLD FLANGE

CONNECTIONS

- PIPE FITTINGS

- PRESSURE RELIEF VALVES

- LINE STRAINERS

- FLOW METERS

- BOOM NOZZLE

PIPE ADAPTERS

- PUMPS

-

PLASTICON

PLASTICON- Catalogue DOWNLOAD

- APS FLANGE SPRAY SHIELD CATALOG

Advance Products & Systems Inc., which was established in 1978, is a leading manufacturing and distribution company for pipeline products that are used for water, waste-water, oil & gas, industry and machines, and chemicals.

APS also provides quality safety products that are designed for protecting employees, devices, and the environment. Advance Products & Systems Inc. have been dedicated to manufacturing high-quality pipeline products that can provide reliable products to customers based on its excellent reputation for 39 years.- Safety Shields Materials / Design

-

•Non-Metallic and Metallic Materials

•ANSI, DIN, JIS, BS, available in various pressure ratings

•Custom designs available

PTFE SPRAY SHIELD

PTFE coated glass cloth

PTFE or Nomex thread and drawstring

Maximum operating temperature 450º F

Fire and tear resistant

Available in five styles: premium,

standard, single-ply, clear PTFE and PTFE whiteStandard color is brown

Broad spectrum of chemical resistance

POLYPROPYLENE SPRAY SHIELD >

100% black polypropylene cloth, thread, and drawstring

Polypropylene stiffener lines the interior for added protection

Maximum operating temperature 200º F

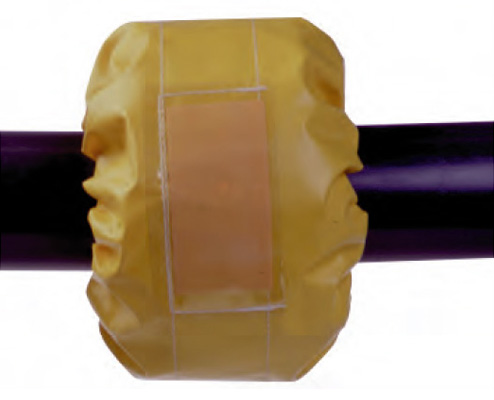

PVC SPRAY SHIELD

Manufactured from yellow, reinforced

polyvinyl chloride (other colors available)Reinforced thread and drawstring

Maximum operating temperature 170º F

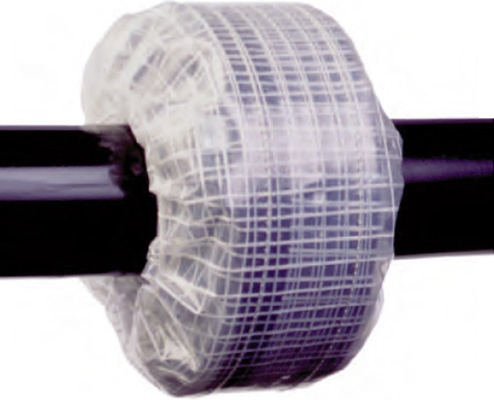

POLYETHYLENE SPRAY SHIELD

Manufactured from transparent,

reinforced polyethyleneReinforced thread and drawstring

Maximum operating temperature 170º F

METAL SPRAY SHIELD

Recommended for corrosive and hazardous environments

Available in 304 and 316 grade stainless

Maximum operating temperature 2,000º F

Maximum operating pressure 3,500 psi

-

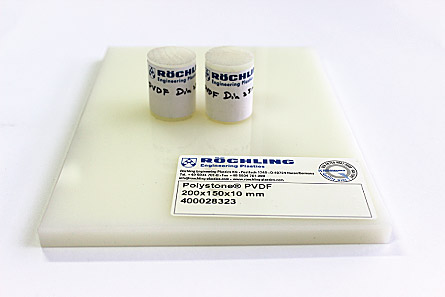

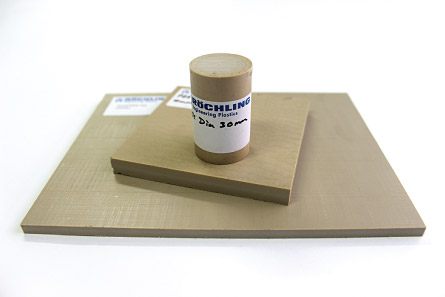

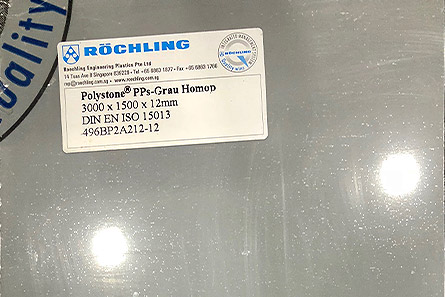

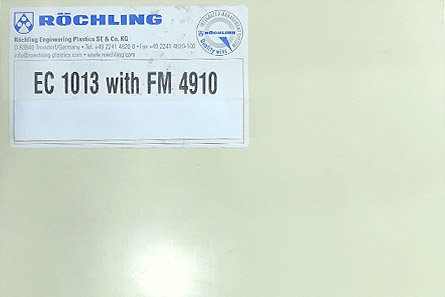

RO”CHLING

RO”CHLING- Catalogue DOWNLOAD

- Chemical Processing Industry Semi finished products

PP, PVDF, PPC, PPS, FM PVC, MHMW-PE SHEET

Since its foundation in 1822, Rochling Group has been manufacturing and selling plastic sheets over the last 90 years. The group has 60 work places in 21 countries where 8,000 employees work.

In the group, there is the high-performance plastic division and automobile plastic division. Especially, Rochling group specializes in producing and supplying PP SHEET(GRAY,NATURAL,WHITE), PVDF SHEET, PVDF-SK, PP-SK, and UHMW-PE.

- PP GRAY TANK

- PP Pickling Tank

- PP Natral Equipment

- PVDF

- PP Gray Tank, Scrubber

- PEEK

- Foam tanks used for PPC fire trucks

- PPS flame retardant sheets

- FM PVC

-

PLASTICON

PLASTICON- Catalogue DOWNLOAD

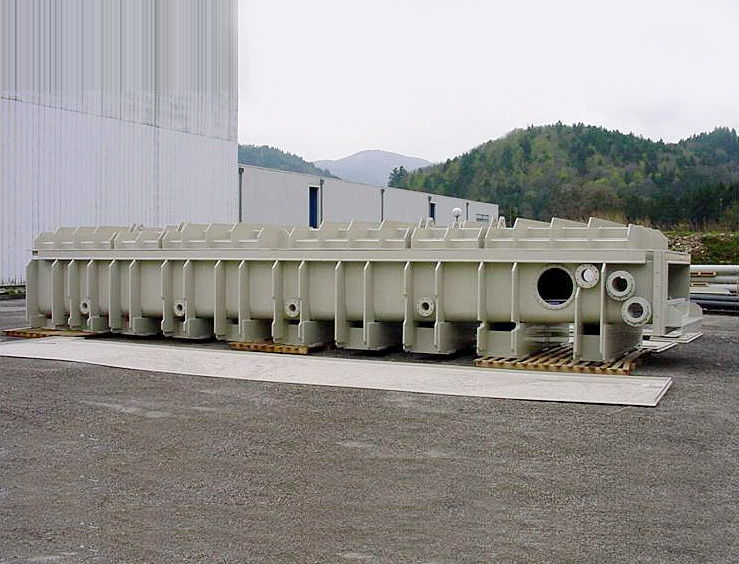

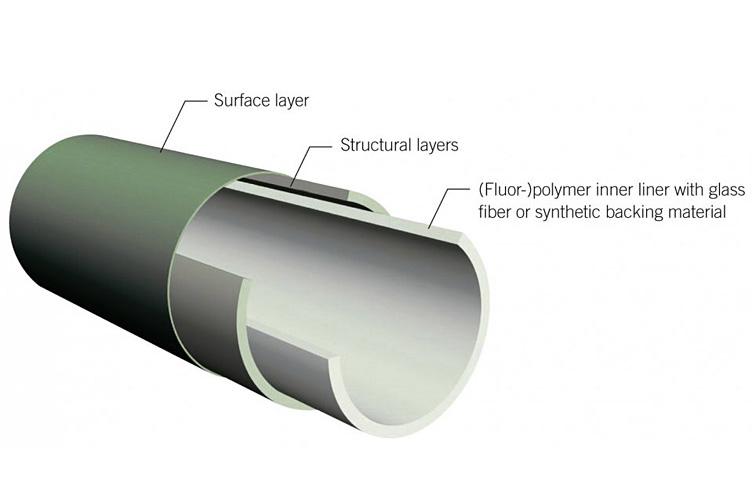

- Piping Systems Corrosion Resistant Solutions Chemical Process Industry Power

PP+FRP, PVC, CPVC+FRP Dual laminate Pipings

Founded in 1952, Plasticon manufactures and supplies dual laminate piping systems used in the chemical industry.

Dual Laminate Piping systems are produced in combination with thermoplastic resin or fluoroplastic resin with excellent corrosion resistance and GRP(FRP) with mechanical intensityUse Area Applied Product Power Plant GRP(FRP) Piping Systems Chemical Processing Dual Laminate Piping Systems Water Treatment, Waste Water Material : Thermoplastic Lined GRP

ㆍPVC, CPVC, PP, PE, PVDF, E-CTFE, FEP, PFA, MFA

ㆍISO 14692 & AWWA 45Metal Production Process, Mining GRP(FRP)Process Devices Food & Beverage Material Chimney & Duct Waste Matter Incineration Other Special Product

- GRP – FRP Pipe

- Pressure Test

- GRP/Dual Laminate Process Vessels

- Chemical Processing

- Fluoroplastic Resin Lining Tank

- FRP Tank

- Storage Piping Process(Power)

- Large Power Station Project

- PVC+FRP Dual laminate 배관

Material and Temperature of thermoplastic resin and fluoroplastic resin used for Dual Laminate PE PVC CPVC PP PVDF EDTFE FEP MFA PFA Modified PTFE e.g TFM max 60℃ max 60℃~70℃ max 85℃ max 90℃ max 100℃ max 110℃ max 140℃ max 160℃ max 180℃ max 200℃ -

ESP Gasket

ESP Gasket- Catalogue DOWNLOAD

- ESP Gasket

ESP Gasket

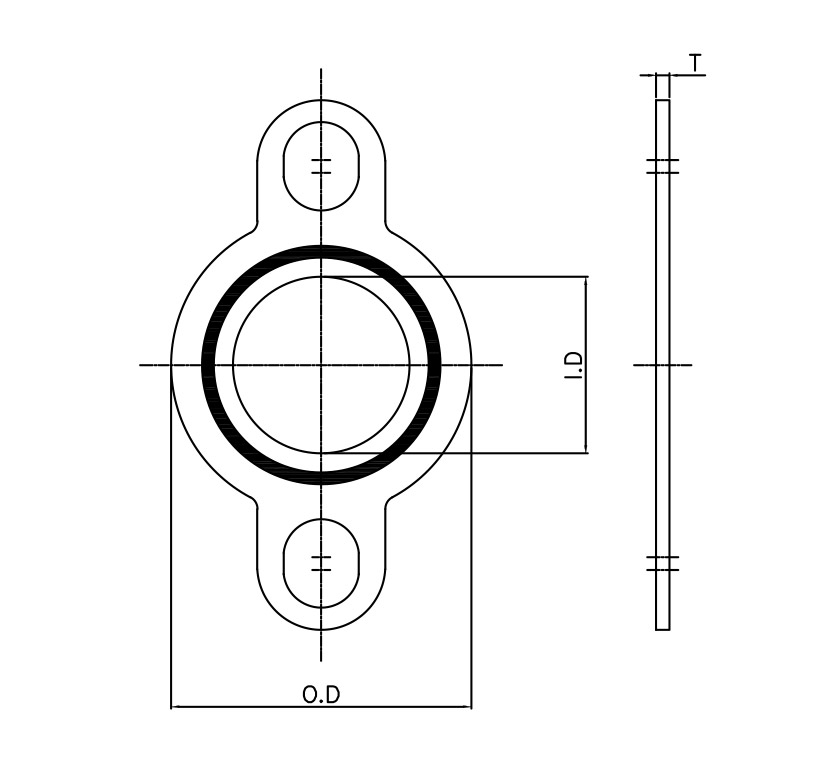

ESP (Enhanced Spreme Protection) Gasket

ESP gasket has passed a metal fusion performance test by using e-PTFE as a raw material. We are providing products that are optimized for pipes that require ultra-pure and pure semi-conductors.Product Specification Material e-PTFE Application UHP PVDF, HP PVDF, CLEAN PP, RF FALNGE 용 NORMAL PVDF, PP, RF FALNGE 용 Standard FLANGE : JIS 10K STUB FLANGE : JIS (SDR 21) Product Range 15A ~ 200A Color WHITE - Dimension

Flange Size O.D I.D T Weinght(kg) 15A 1/2” 45 14.7 3 0.005 20A 3/4” 58 20.3 3 0.006 25A 1” 68 26.1 3 0.009 32A 1 1/4” 78 33.6 3 0.012 40A 1 1/2” 84 42.8 3 0.014 50A 2” 99 55.1 3 0.015 65A 2 1/2” 119 66.4 3 0.016 80A 3” 129 80.0 3 0.023 100A 4” 154 98.0 3 0.030 125A 5” 185 128.8 3 0.040 150A 6” 212 143.0 3 0.052 200A 8” 265 202.3 3 0.070

SEKISUI

SEKISUI SPEARS

SPEARS HARVEL(G.F)

HARVEL(G.F) IPEX

IPEX FIP

FIP SHIE-YU

SHIE-YU IPS WELD-ON

IPS WELD-ON HAYWARD

HAYWARD CLIC

CLIC BANJO

BANJO APS

APS ROCHLING

ROCHLING PLASTICON

PLASTICON GASKET

GASKET